Primary components of Pallet Rack Systems

Pallet racks, or pallet racking systems, form the interior skeleton of most American warehouses. Racks make your pallet storage and retrieval simple and safe. That’s provided you’ve determined your pallet rack weight capacity and never exceed it.

View Our Pallet Racking solutions

You’ve probably wondered how much weight you can put on pallet racking, and how storage rack capacity is calculated. Engineers and designers determine pallet racking load limits by taking stock of the structural load-bearing capacity of each rack system component. Combined, each component contributes to your rack’s integrity, and this is how they determine rack capacity.

Calculating warehouse racking capacity is a mathematical exercise more than a theoretical expedition. Engineers are practical people, and they follow known information such as proven tables that prescribe known weight limits for rack components based on their physical size and metallurgic composition. From existing information, they know how to calculate pallet rack load capacity.

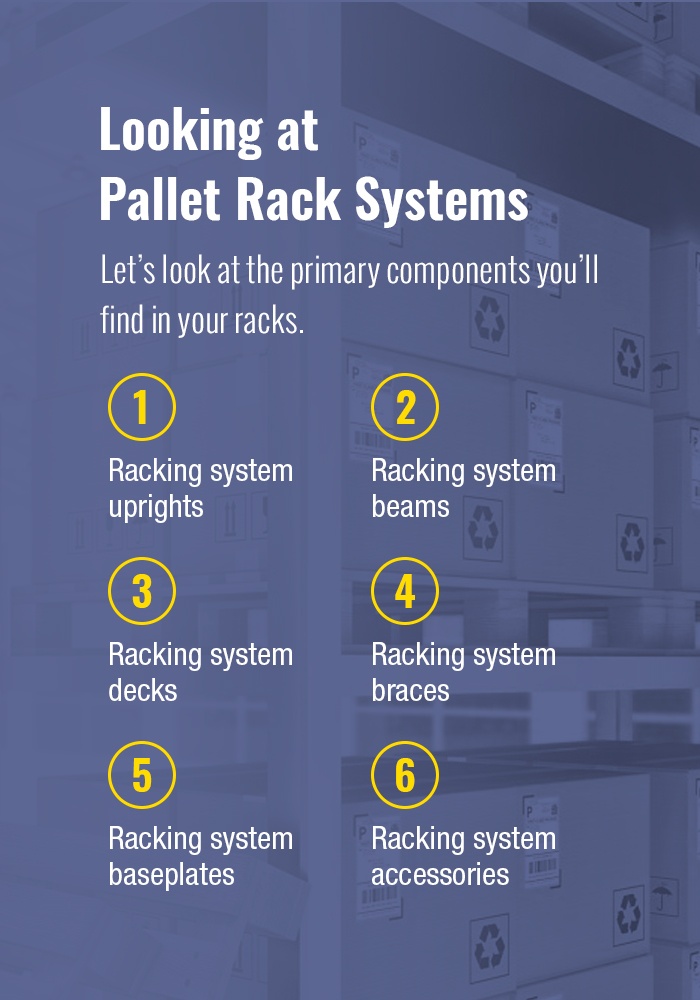

Looking at Pallet Rack Systems

By definition, rack systems are combinations or assemblages of parts that form a solid whole. Warehouse rack systems are a set of correlated members that tie together making an organized structure capable of supporting a limited weight in loaded pallets. It’s a case of the whole arrangement being a sum of its parts.

Each pallet rack system part or component serves one purpose. That’s to transfer gravitational pull or weight to the ground. However, each rack component acts individually, and they work in conjunction with other parts to get their job done. Before delving into how you determine pallet racking system weight limits, let’s look at the primary components you’ll find in your racks.

- Racking system uprights: These are the vertical or upright rack system members. They form the left and right sides of a rack assembly and direct weight transferred by the rack’s beam and deck components to the floor. Uprights are under a compression force as the load weight gets pushed to the ground.

- Racking system beams: Beams are the rack’s horizontal members that connect the uprights at various intervals. Distances between beams depend on loaded pallets’ expected height. Beams are also called cross-members, and they’re under both compression and tension forces as they pick up pallet weight and laterally transfer it to the uprights.

- Racking system decks: Horizontal platforms traversing the beams are commonly called decks or decking. These platforms can be solid surfaces or perforated shelving called wire decking. Decks take concentrated or point loads from support joists built into the pallets and uniformly spread the weight onto the beams.

- Racking system braces: Braces give pallet rack uprights torsional rigidity. This structural insurance prevents loaded upright components from twisting and integrity loss that results in rack failure. Without diagonal and horizontal braces, a rack assembly would be highly prone to buckling and a disastrous collapse.

- Racking system baseplates: The ground absorbs weights in rack systems. In warehouses, most floors are concrete, and they serve as a buffer to release downward loads from the pallets, decks, beams and uprights into horizontal weight transfer back to nature. Baseplates are the final intermediary between the system components and the floor, and they work to secure each upright leg as it connects to the final load load-bearing surface.

- Racking system accessories: Although rack systems work well as integral components, a total system usually relies on accessories for additional security. Upright and baseplate protectors are typical accessories that protect a rack system from one of its most significant threats — dynamic forces caused by a forklift collision.

Contact T.P. Supply for All Your Pallet Racking Needs

T.P. Supply is your best partner for determining your pallet rack capacity. We’ve worked with warehouse owners, operators and managers since 1979. Since then, we’ve specified thousands of fail-safe racks for businesses across America and beyond.

Reach out to T.P. Supply today for your rack systems and other material handling equipment. Call us at (877) 302-2337 or contact us online.